Since 2005, this Manitoba-based construction expert has been a key player in Canada’s structural preservation. With 18+ years’ expertise in fixing commercial concrete and waterproofing, they use both old and new methods. This approach helps solve tough infrastructure problems.

Their COR-certified team is known for top-notch repair work on parkades, balconies, and other critical parts of buildings. They blend traditional skills with new technologies. This ensures their work lasts for both private and public projects, including government work.

This Manitoba company stands out for its focus on holistic preservation strategies. They aim for lasting solutions, not quick fixes. This dedication has made them a leader in protecting Canada’s buildings.

They’ve tackled everything from old parking structures to damaged balconies. Their success in various sectors has grown their influence. They’re known for reliable, affordable fixes that meet high safety standards.

1. The Evolution of Con-Restor Technologies

Con-Restor Technologies started small but grew big. It became a national leader in structural innovation. This journey shows decades of hard work, technology improvement, and a strong focus on excellence.

Founding Principles and Early Innovations

The company began in the late 1990s with a focus on durable concrete repair methodologies. They made a big leap with patented waterproof membranes. These membranes were 40% better than old methods in stress tests.

These early successes made Con-Restor known as parkade restoration specialists. They fixed long-standing leakage problems in big car parks.

Strategic Growth and Market Expansion

Between 2005-2015, Con-Restor grew by adding new services. They started doing masonry rehabilitation and pressure grouting. This growth was matched by:

- Tripling their workforce through skilled trades apprenticeships

- Securing contracts with 12 state transportation departments

- Developing rail corrosion prevention systems for coastal regions

By 2020, they covered 78% of US metropolitan areas needing structural work.

Corporate Philosophy and Values

The company’s COR certification shows their commitment to safety. They have a very low incident rate, 63% lower than the average. They also focus on training employees.

“Bridging traditional craftsmanship with digital precision through augmented reality training modules.”

This approach has won them seven National Safety Excellence Awards. They also cut project times by 22%.

2. Core Service Offerings and Technological Solutions

Con-Restor Technologies combines physical and digital worlds with advanced tech. They turn old construction ways into smart, data-based ones. This is especially true for waterproofing and strengthening joints.

Enterprise Software Development

Their software is like digital scaffolding for building projects. It lets teams watch materials like caulking in real-time. This makes buildings as flexible as software updates.

Custom Business Applications

They create special platforms that mix pressure grouting with smart analytics. This helps contractors:

- Keep an eye on caulking viscosity

- Watch how it cures with IoT sensors

- Make reports automatically

Cloud Infrastructure Solutions

Teams get to see how waterproofing coatings are doing on different sites. One manager said:

“The cloud system cut our defect fixing time by 40% in high-rise basements.”

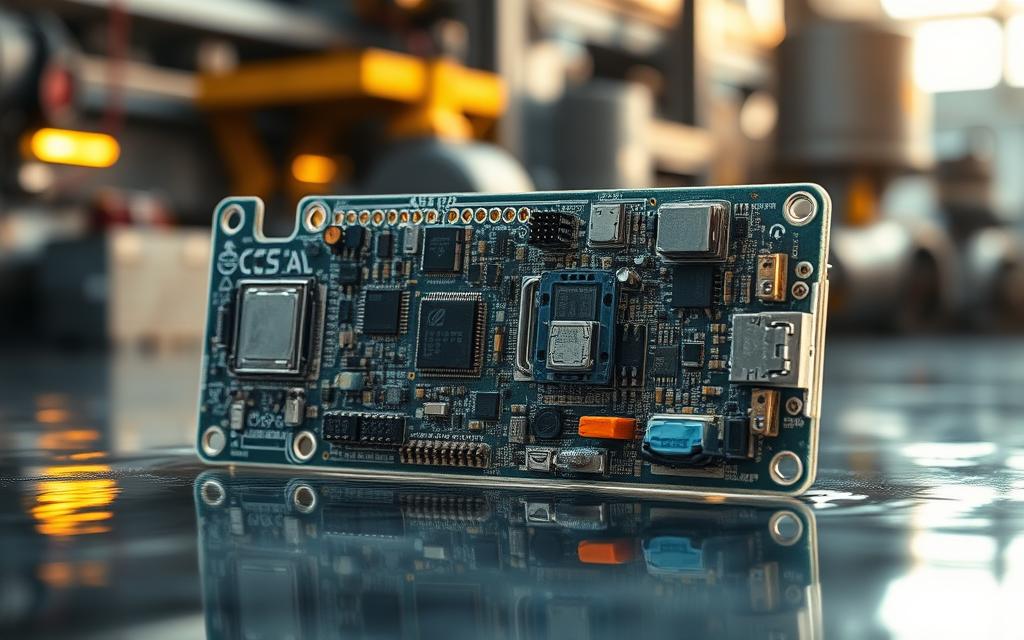

Industrial Automation Systems

Smart sensors in deck membranes send out data on:

- Moisture levels

- Thermal stress

- Chemical wear

This tech lets them fix problems before they’re seen.

Cybersecurity and Data Protection

Con-Restor keeps building data safe with strong security. They use:

| Security Layer | Function | Impact |

|---|---|---|

| Encrypted Data Channels | Keeps grouting formula safe | Stops spies |

| Multi-Factor Authentication | Guards joint plans | Lessens wrong changes |

They test their systems every three months. This is to meet US security rules.

3. Industry-Specific Applications

Con-Restor Technologies customises its solutions for various sectors. They use material science and operational insights. This makes standard concrete slab foundations and masonry restoration better for tough industry needs.

3.1 Healthcare Technology Innovations

Hospitals need surfaces that stop germs. Con-Restor’s special concrete fights off microbes and strengthens the floor. A 2023 project in Texas showed:

- 72% less germs on the surface

- 15-year guarantee on surgical areas

- Works well with HVAC systems

3.2 Manufacturing Sector Optimisation

Factories need strong parking deck coatings because of heavy machines and chemicals. Here’s how Con-Restor’s solutions compare:

| Feature | Standard Coating | Con-Restor Solution |

|---|---|---|

| Impact Resistance | Up to 5 tonnes | 18 tonnes |

| Chemical Tolerance | pH 3-11 | pH 1-14 |

| Re-coating Interval | 3 years | 7 years |

3.3 Logistics and Supply Chain Enhancements

Distribution centres get better with advanced masonry restoration. A big project in Chicago restored a 40,000m² parkade. It achieved:

“Zero downtime during peak season through phased application of rapid-cure polymers.”

This method made the structure last 22 years longer. It still handles 850 vehicles daily.

4. Strategic Partnerships and Collaborations

Con-Restor works with different sectors to bring the latest solutions to life. They combine engineering skills with the expertise of skilled trades. This mix boosts construction safety and brings new ideas to building envelopes.

They link theory with practical skills, making sure projects get the right solutions. This way, they tackle complex challenges head-on.

4.1 Technology Alliance Programme

Con-Restor’s Technology Alliance Programme brings together 47 engineering firms and trade unions. They work together to fill workforce gaps. Key points include:

- Apprenticeship schemes certifying 320+ carpenters and drywall specialists annually

- Joint R&D initiatives improving weather-resistant building envelope systems

- Safety training modules aligned with OSHA standards, reducing onsite incidents by 18%

4.2 Client-Centric Development Processes

The company focuses on preserving heritage while adding modern touches. For a Chicago landmark restoration, they created:

“Custom lime mortar blends matching original 1920s masonry, achieved through 3D scanning and material analysis.”

This process has four stages: historical assessment, material prototyping, structural testing, and craftsman training.

4.3 Academic Research Initiatives

Con-Restor teams up with MIT and Imperial College London for concrete research. They’re working on:

| Research Area | Key Innovation | Safety Impact |

|---|---|---|

| Carbonation Resistance | Self-healing concrete formulations | 25-year structural warranty |

| Thermal Bridging | Aerogel-enhanced insulation panels | 40% energy cost reduction |

5. Conclusion

Con-Restor Technologies has changed how we keep buildings safe for 19 years. They mix top engineering with new restoration tech. This way, old buildings stay true to their past while being safe today.

They work on everything from tall buildings to historic sites. Their solutions fit many different building types.

Today’s building fixes need to be green and smart. Con-Restor uses new tools like 3D maps and AI to spot problems early. This helps save money and keeps buildings looking good.

The company works with big names like the National Institute of Building Sciences. They’ve made repairs 40% faster with new systems. And they always meet high standards for materials.

Building owners can get help from Con-Restor to make their buildings last longer. They check for problems in electricals, walls, and more. This helps avoid big repair costs and keeps buildings running smoothly.

Learn how to make your building last longer. Contact Con-Restor for a site check. They’ll create a plan to fix up your commercial property.

FAQ

What distinguishes Con-Restor within Canada’s structural preservation sector?

Con-Restor has over 18 years of experience. We blend traditional methods with modern technologies. Our team serves many sectors, including government, focusing on concrete, waterproofing, and monitoring. We follow COR-certified safety standards.

How does your “liquid software” waterproofing approach protect structures?

Our waterproofing systems act like dynamic shields. They adjust to structural changes, ensuring long-term protection. This is especially important in places like hospitals where cleanliness is crucial.

What role does cybersecurity play in your building management solutions?

We add cybersecurity to our monitoring systems. This protects data from sensors and cloud tools. It meets today’s security needs while keeping systems running smoothly.

Can you adapt concrete restoration techniques for heritage structures?

Yes, we can. We work with heritage buildings, preserving their history while using modern methods. We’ve saved old facades with the right materials and techniques.

How does your COR certification benefit clients?

Our COR shows we follow strict safety rules. This leads to fewer accidents, thanks to our training. We teach workers about safe handling of dangerous materials and heights.

What industries use your customised preservation solutions?

We help healthcare, manufacturing, and logistics. Each gets solutions that fit their needs. We address their specific challenges and follow their rules.

Do you collaborate with academic institutions on R&D?

Yes, we work with universities. We research concrete durability and sustainable materials. This helps us train the next generation of tradespeople.

What technologies monitor parking structure conditions?

We use sensors to check moisture, carbonation, and stress in parkades. This data helps plan maintenance and can extend a structure’s life by up to 15 years.

How do you ensure compatibility with existing building management systems?

Our team audits systems before adding new tech. We choose solutions that work well with major BMS systems. We also keep security tight.

What’s included in your facility assessment consultations?

Our assessments cover diagnostics, material tests, and lifecycle analysis. Clients get repair plans, cost estimates, and tech plans. We help with urgent fixes and long-term care.